|

|

|

color photo courtesy of George Pitz (Thanks, George!!)

Below is a detiailed description of the Orangeville locomotive facility boiler washout system, taken from the American Engineer and Railway Journal, Volume 84 - December, 1910:

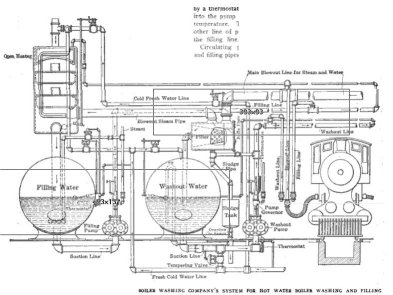

Recognizing the very great value of a hot-water wahsing-out and filling system,not only as a time saver in turning locomotives but also as ameans of reducing flue leakage and engine failure on the road the New York Centeral Lines have installed systems of this kind in practically all of the enginehouses built in the past four or five years. Most of the equipment installed are of the same design as Corning, which was manufactered and [in]stalled by the National Boiler Washing Co. of Chicago. One of the illustrations shows, in diagrmamatic form, the apparatus and piping connectins as used by this system, in which the utmost care has been taken to make it thoroughly automatic in its operation and positive in its result. An investigation at the terminal under discussion shows thaht the engineer in power plant found it necessary to to simply lubricate the pumps and occasionaly blow out the sludge tank, and beyond this no attention was found needed, the pressures, temperature, stc. being sustained within narrow limits.

Bouler washout system

Referring to the diagram, it will be seen that a locomotive coming in to be washed out is first connected by a hose to the blow-offline, the plug for which is located on every alternate post of the inner circle. From this connection it discharges into the main blow-off pipe. which is carried from the roof timbers around the circle, as is shown in one of the photographs, continuing to the powerhouse, where it discharges into a large closed filter. In passing into the filter it operated a flap valve, which in turn automatically opens a valve in the cold water line to the top of the open heater. The steam and water passing into the filter hit a baffle plate, and the steam is deflected into the blow-off steam pipe to the open heater located ablve the filling-water reservoir. Here the steam is condensed by the cold water and flows to the storage tank below. A thermostat in this storage tank controls a valve on the live steam line, and live steam is admitted to it whenever the temperature is below that desired usually 170to 180 degrees. As a matter of fact, this valve is seldom operated, as the steam from the low-off water is usually sufficient to maintain the proper temperature, In this tanl there is also a float connecting to a valve on the cold water lineinsuring a sufficient supply of water at the proper temperature for filling at all times.

A large, pwoerful pump draws its supply from this tank and discharges it into the filling line that parallels the the blow-off line in the circle around the house and has a drop pipe with a gate valve on the same post between every two pits.

The blow-off water, after reaching the filter, passes through a cone inclosing filtering material, after which it is discharged into the washout water tank just below. The sludged and scale held back by the filter are discharged into the sludge tank, from which it can be washed into the sewer. The tempeerature of the water in the washout tank as it comes from the filter will be on an average of about u185 degrees, but as this is too hot to handle in a washout hose, an automatic device is provided for maintaining it at a lower temperature, usually about 130. A valve is placed in a connection between the fresh water line and the suction line for the washout pump and ic controlled by a thermostat in this suction pipe, so that cold water is drwan into the pump supply in the proper amount to give the desired temperature. The discharge from the pump is carried in another line of piping through the house in the same manner as the gilling line.

Circulating pipes extend from the ends of the washout and filling pipes back to the tanks and allow the pumps to be kept in slow motion all the time, not only maintaining the temperature in the long piping, but also insuring the pumps being ready to act more promptly when needed. The filling pump has a capacity of 500 gal. per minute and the washout pump has a sufficient capacity to wash out three boilers at one time, maintaining a pressure of 90 lbs. The filling water tank has a capacity of about 12,000 gallons and the washout tank of about 8,500 gallons.

|

even if you tie, you lose |

|