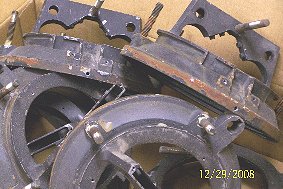

To begin

with, the shades/hoods/visors - whatever you want to call them - are HEAVY guage steel and are

LARGE - in the picture to the right, dimension W is 10 inches and dimension L is

eight and one-eighth inches. I could clean the entirety of the convex surface (the

outside) with the sanding drum setup but could only get three inches in toward the center from each side on the concave

surface (the inside) because the edges of the hoods kept hitting the chuck on the drill press.

Oh well..at least I only had to sand a 2-inch-wide band by hand instead of the entire

hood!

To begin

with, the shades/hoods/visors - whatever you want to call them - are HEAVY guage steel and are

LARGE - in the picture to the right, dimension W is 10 inches and dimension L is

eight and one-eighth inches. I could clean the entirety of the convex surface (the

outside) with the sanding drum setup but could only get three inches in toward the center from each side on the concave

surface (the inside) because the edges of the hoods kept hitting the chuck on the drill press.

Oh well..at least I only had to sand a 2-inch-wide band by hand instead of the entire

hood!

The hoods, which resemble the face shield of a suit of armor, took the longest to clean - almost 20 minutes each - and wore out three sanding sleeves because of deposits of creosote, which had dripped from the walkway of the signal bridge when it was parged, on two of them.

Next were the plates that protect the wires going into the lamp unit - small T-shaped pieces

that took about 15 seconds each to clean up. Then it was time to tackle

the "bezel rings" - large pieces of metal, shaped sort of pie pans with handles on the back,

to which everything else is attached. The odd angles and the lips/ridges on these made

them difficult to sand with machinery - I had to do most of the sanding by hand.

Next were the plates that protect the wires going into the lamp unit - small T-shaped pieces

that took about 15 seconds each to clean up. Then it was time to tackle

the "bezel rings" - large pieces of metal, shaped sort of pie pans with handles on the back,

to which everything else is attached. The odd angles and the lips/ridges on these made

them difficult to sand with machinery - I had to do most of the sanding by hand.

Before I did the bezel rings, however, I decided to get the small things out of the way: dozens

of screws, washers, nuts and knobs. They all needed to be cleaned up - some were so bad

the metal was pitted - and they all had to be done by hand. Fortunately my wife got me a

toy that I asked for for Christmas - a 300 series Dremel rotary tool. I went out and got

a flex shaft attachment, and the task cleaning dozens of small pieces went from a nightmare to

two nights of ease (well, easier than sheets and sheets of 220-grit sandpaper, untold nights at

the workbench, and cramped fingers...).

Before I did the bezel rings, however, I decided to get the small things out of the way: dozens

of screws, washers, nuts and knobs. They all needed to be cleaned up - some were so bad

the metal was pitted - and they all had to be done by hand. Fortunately my wife got me a

toy that I asked for for Christmas - a 300 series Dremel rotary tool. I went out and got

a flex shaft attachment, and the task cleaning dozens of small pieces went from a nightmare to

two nights of ease (well, easier than sheets and sheets of 220-grit sandpaper, untold nights at

the workbench, and cramped fingers...).

Continued...

Continued...

Back to Mike's Railroad Page

Back to Mike's Railroad Page